The BLUEline rotary lobe pump is our proven “continuous runner”. 20 pump sizes and the large selection of materials and rotors (different geometric designs and materials) allow an individual design of the pump adapted to your application.

The ONIXline rotary lobe pump is the flagship of our pump range. The newly developed rotors in a flow-optimized pump casing in combination with the very robust carrier and timing gear ensure the best efficiency even with high pressures. The ONIXline offers the highest flexibility when selecting the sealing system.

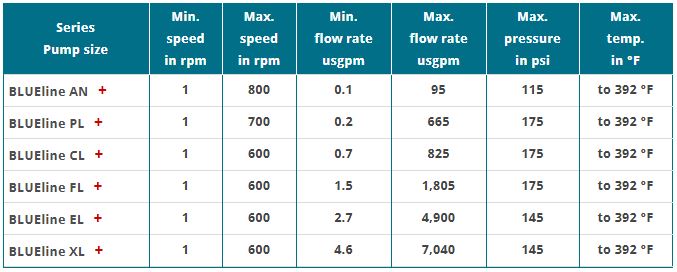

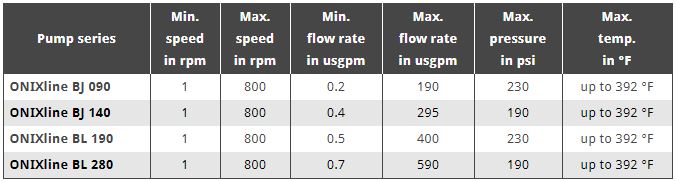

Pump Capacity

| BLUEline Series | ONIXline Series |

| Flow rates of 4.4 – 7,050 usgpm (1 – 1,600 m³/h) | Flow rates of 4.4 – 595 usgpm (1 – 135 m³/h) |

| Pressure-resistant up to 174 psi (12 bar) | Pressure-resistant up to 232 psi (16 bar) |

| Highest flexibility when it comes to rotors | Highest flexibility when it comes to the sealing system |

BLUEline rotary lobe

ONIXline rotary lobe

Applications:

Oil and Gas Industry

Chemical Industry

Paper and Textile industry

Marine and Offshore

Sugar and Food Industry

Municipal and Disaster Relief

Agriculture and Biogas Industry

Additional Specifications

Börger Rotary Lobe Pumps are self-priming , valveless, positive displacement pumps. The even rotation of the rotor pair creates a vacuum on the priming side of the pump, which can be defined by the direction of rotation of the drive. This vacuum draws the liquid into the pump chamber. With further rotation, the pumped medium is conveyed past the pump wall into the pressure area. Up to six chamber charges are displaced with each drive rotation– depending on the rotor type. When the rotor is at a standstill, the pump seals off almost completely.