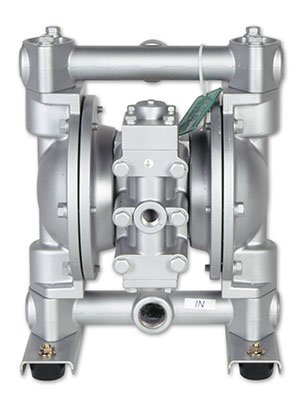

Diaphragm Pump NDP Series pumps are the backbone of the industrial line of AODD pumps. A unique, patented air-valve design ensures stall-free operation. Bolted construction and common component replaceable parts maximize uptime and increase profitability.

Yamada air valve technology is the heart of the air-powered double diaphragm pump and determines reliability. Yamada holds three patents on its field proven valve. The patented Yamada® Air Valve on all NDP series pumps never requires lubrication or pre-packing. The advanced design eliminates the need for external lubrication, which can lead to pumpage contamination and maintenance headaches. All Yamada air valves can be restored with individual components, without requiring complete valve and housing replacement. Many competitor including Wilden AODD, Sandpiper AODD and Graco AODD incorporate an air valve with complicated designs which requires complete replacement of the valve assembly and housing, further increasing the cost of ownership.

Some of the Pump Diaphragm considerations – chemical resistance, cost, estimated flex life, temperature limitations and abrasion resistance. Rubber compounds include Neoprene, Buna-N, EPDM and Viton. All pumps have a comprehensive repair kits and complete parts breakdowns available along with maintenance manuals.

YAMADA ADVANTAGE

Bolted Construction

All Yamada pumps feature bolted construction, which eliminates leaks and simplifies post-maintenance reassembly. Bolted construction is superior to clamp band retainers, which frequently require frustrating, unnecessary leakage rebuilds from misalignment during reassembly.

Outside-Accessible Air Valve

Inspection or maintenance of every Yamada air valve may be performed without removing the pump from service. Outside accessible, making it easy to fix / inspect.

Unified Air Valve Concept

Common-size air valve assemblies reduce parts confusion.

Pilot Valve

Unique to the Yamada design is an individual modular pilot valve that actuates the air valve. It is depressed slightly by the inner center disk creating a pressure drop at one end of the air valve, allowing shifting to occur. It is maintenance free with no cumbersome snap rings or lubricated dynamic o-rings to replace or repair.

Applications:

Industrial Applications

Alternative Energy

Environmental Remediation

Automotive Fluid Transfer

Chemical Pumps

Food, Cosmetics and Pharmaceuticals

Mining Applications

Petroleum Oil & Gas

Paint & Coatings

Brewery Pumps

Powder Pumps

Wine and Winery