Fybroc pumps are produced using a Resin Transfer Molding (RTM) process that allows a controlled placement of long strands of fiberglass reinforcement in high stress areas. this allows for a thinner wall structure with optimum corrosion resistance.

Critical components such as the casing and its gusseted suction and discharge flanges benefit from the reinforcing properties of the RTM process. The method reinforces the casing to extend the life and provides unparalleled strength in corrosive environments. The pumps are designed using one material to cover a wide range of chemical applications and adds to a high degree of interchangeable parts.

Major Markets

Chemical

Steel

Pulp and paper

Electric utility

Aquaculture/aquarium

Industrial waste-water

Types of Pumps:

Horizontal Pumps -ANSI & close coupled

1500 Horizontal Fiberglass Pumps

1530 Close-coupled

2530/2630 Close Coupled Sealess

3000 Recessed Impeller

Self Priming Pumps

1600/1630 Self-priming pumps

Vertical & Cantilever Sump Pumps

550 Vertical Sump Pump

5530 Vertical Dry Pit Pump

7500 Cantilever Pump

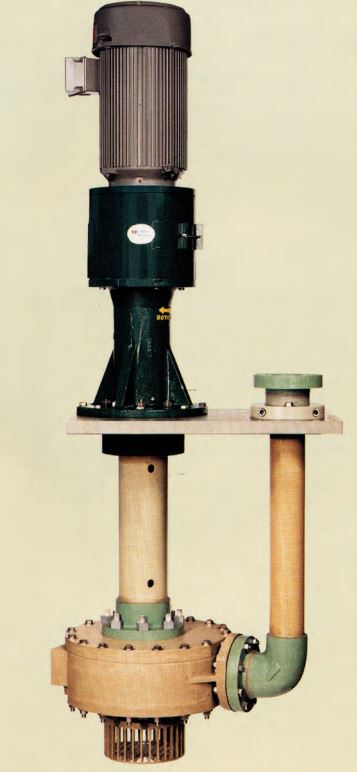

Vertical Turbine Pumps

Series 8500

Mag-Drive Pumps

Models