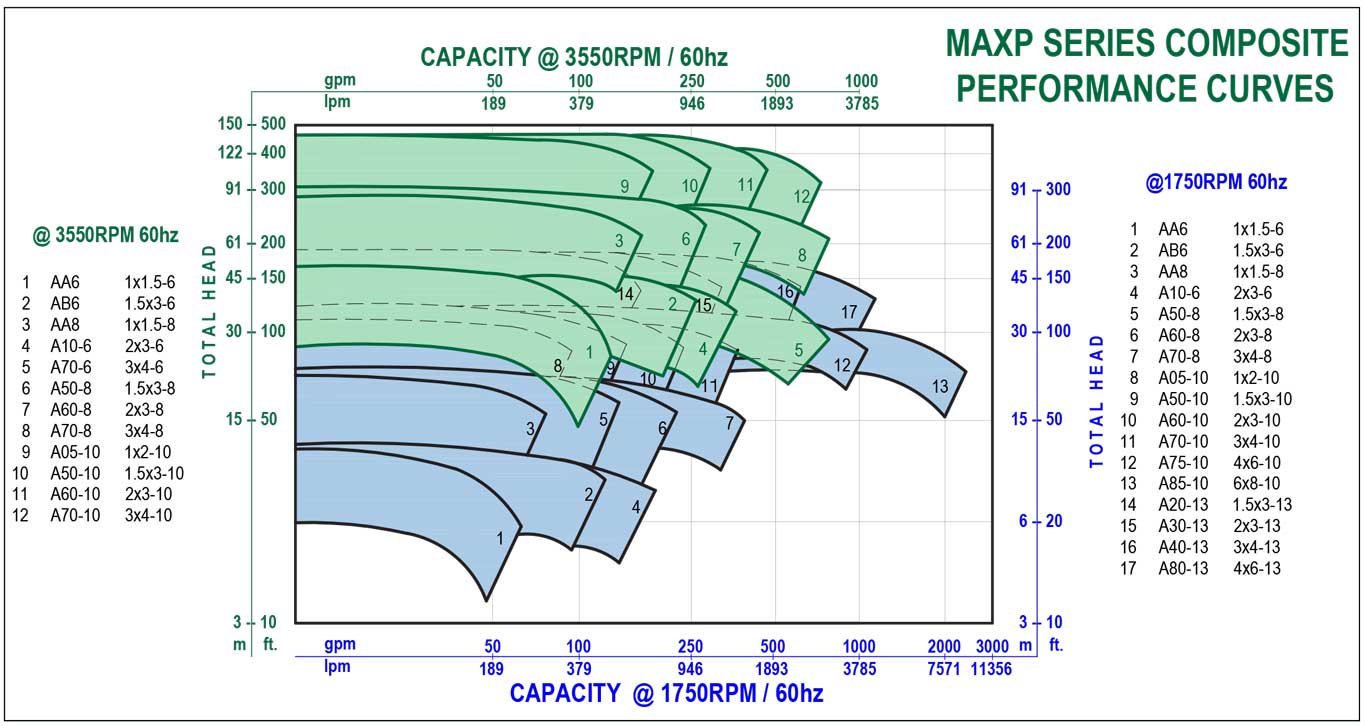

This Pump was built for Formic acid / Hydrogen peroxide 400 gpm @ 100 TDH, 140°F.

Magnatex MAXP pumps have the following design features:

- Mag drive sealless pumps eliminate the need for expensive mechanical seals; eliminating costly shutdowns and repairs, which helps reduce “Reportable Release” issues.

- No maintenance intensive mechanical seals required. No seal flush or complex and expensive seal pot systems to monitor or maintain.

- Straddle-mounted inner magnet system with bearings on both sides of the magnet – this design reduces shaft and bearing loads when compared to our competitors overhung, cantilevered, inner magnet designs

- Slip-fit construction, which allows easy on-site maintenance with no special tools or fixtures required

- Large internal flow paths, which means the pumps can easily handle 1% solids @ 500µ and up to 8% solids @ 100µ. Optional baffle-plated rear casing enables enhanced solids handling capability. Optional proprietary self-cleaning strainer technology enables us to handle even higher solids percentages if necessary

- Safely handles toxic, noxious, corrosive or high-temperature liquids with increased safety to personnel and the environment

- Special high-temperature construction is available to handle up to 800°F

- Options for leak detection are available that virtually eliminate any leakage to the environment when handling extremely hazardous chemicals

Materials of Construction

- 304 SS

- 316 SS

- Duplex Stainless Steel

- Alloy 20

- Alloy B&C