The chemical industry – similar to much of the manufacturing industry, uses water during the production process. Water may be used for either creating products or cooling equipment used in creating products. Industrial water is used for fabricating, processing, washing, diluting, cooling, or transporting a product. Industries producing chemical products use large amounts of water. Regardless of what the water is being used for within the production process, filtration is essential to ensure efficient operations. Sufficient filtration ensures product quality, energy and water efficiency and sustainability.

TYPICAL APPLICATIONS: River Water Filtration, Well Water Filtration, Surface Water Filtration, Process Water Filtration, Cooling Circuit Protection, Cooling Tower Filtration, Polishing of Effluent Prior to Discharge

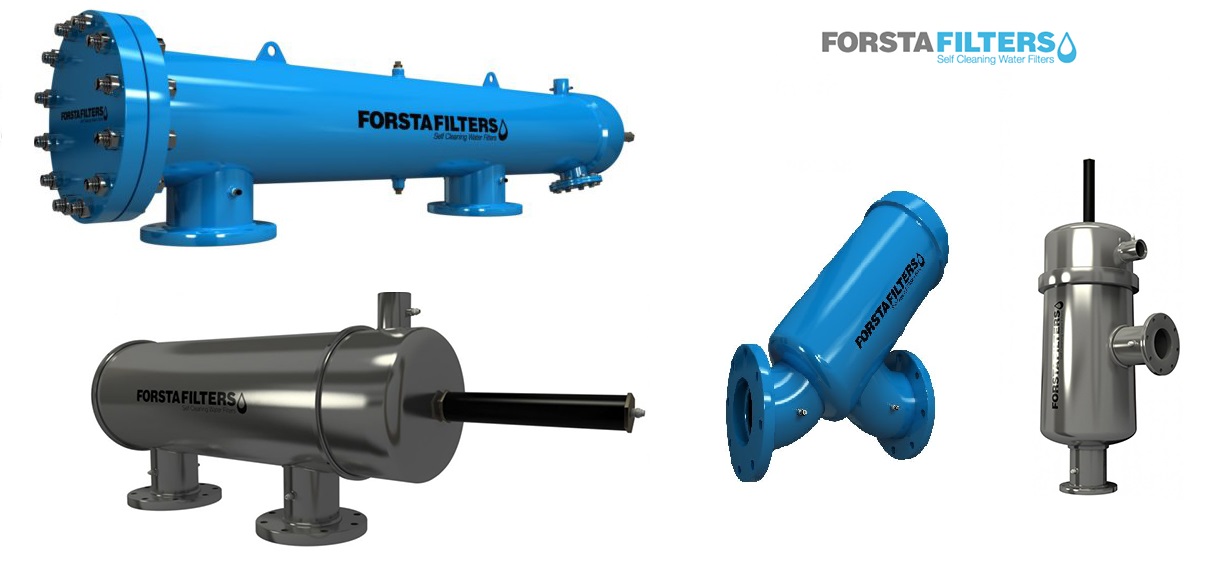

Forsta sea water filters – provide a vital tool for solids removal from raw seawater, and in sea water treatment sequences. Forsta sea water filters are available in corrosion-resistant materials such as fiberglass reinforced plastic (FRP), sometimes referred to as glass reinforced plastic (GRP). Filter bodies are also available in stainless steel, carbon steel with protective coating, titanium and super duplex. These materials provide durable, long-lasting water filtration solutions.

TYPICAL APPLICATIONS: R/O Prefiltration, UF Prefiltration, Raw Seawater Filtration, Cooling Water for HVAC, Process Water Filtration

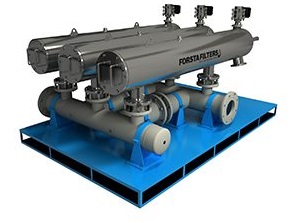

PULP AND PAPER INDUSTRIAL FILTERS – Manufacturers in the paper and board industries require large volumes of high quality water available at low cost. For this reason, incorporating a Forsta industrial water filtration system offers an outstanding solution.

As an alternative to purchasing potable city water, many companies utilize direct water sources such as rivers or lakes. Due to natural particle density it is necessary to filter the water from untreated sources prior to use in an industrial system.

Forsta self cleaning industrial water filters facilitate the use of these water sources as the primary supply for pulp and paper factories, ensuring product quality.

Once water has been used in the pulp and paper process, large volumes of effluent can then be recycled through an industrial water filtration system for lower grade applications such as wash-down or mixing water. The reduction in waste water volume reduces environmental impact, and increases system efficiency.

TYPICAL APPLICATIONS: River Water Sand Removal, Lagoon Water Algae Removal, Sand Filter Replacement, Process Water Recycle, Compressor Cooling Water, Final Effluent Polishing Prior to Discharge, Cooling Tower: Side Stream or Full Flow

MINING WATER FILTERS – Regardless of the resource being mined, water is used for a variety of purposes in mining operations. Water in mine processes may be corrosive, and require the use of corrosion resistant mining water filters. Common filtration applications at mining sites include effluent filtration, intake filtration, process water filtration for dust mitigation systems, wash water, process reuse filtration, precious metal extraction solutions (heap leach) etc. The 180 Fiberglass Reinforced Plastic (FRP) Series filters offer an ideal solution for corrosion resistance in mining filtration applications. Fiberglass Reinforced Plastic, or Glass Reinforced Plastic (GRP) is a composite material or fiber-reinforced polymer made of a plastic reinforced by fine fibers made of glass. All wetted components of the FRP Series self-cleaning filters are constructed from corrosion-resistant plastic or other high alloy materials.

TYPICAL APPLICATIONS FOR MINING WATER FILTERS: Heach Leap Filtration, Brine Effluent Filtration, Process Reuse Filtration, Cooling Water Filtration, Industrial Process Water, Wash Water Filtration