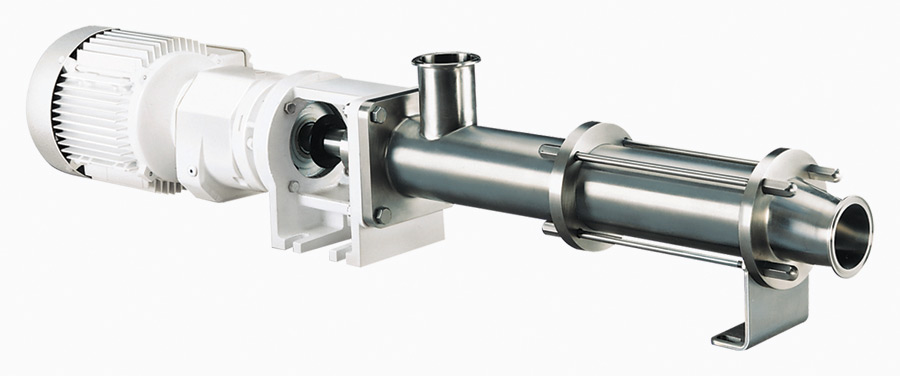

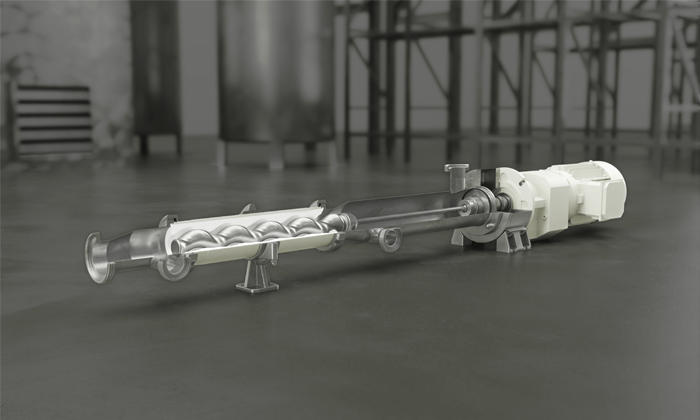

Basic Pump Principle

Moyno® Sanitary progressing cavity pumps gives you all the benefits of positive displacement but also a unique combination of advantages not found in other positive displacement pumps. The pump contains a helical rotor, the screw like rotor turns with in a helical stator to form cavities which move matrials with uniform flow, low RPM. Head is relatively independent of speed.

Unique Advantages

High viscosity up to 1,000,000 centipoises

Abrasives, materials that destroy other pumps can be handled easily in a Moyno® sanitary pumps.

Shear sensitive fluids moves through the pump with minimum physical disturbance.

Non-pulsating & metered flow is uniform, predictable, & accurately repeatable for any liquid or slurry.

Reversible flow, the flow of material can be reversed simply by changing the rotation of the rotor.

Features

- Mechanical seals standard

- Standard models meet 3A and BISSC sanitary requirements with no modifications. Hygienic models are 3-A certification

- Close-coupled and open throat models

Performance Features

- Minimal product degradation in shear-sensitive applications

- Long service life in abrasive slurries and corrosive fluids

- Temperatures to 350° F, viscosities to 1,000,000 cps

- Handle suspended solids to 1.1″ diameter

- Pressures to 225 psi; capacities from .02 to 345 gpm

Typical Applications

- Bread dough & bakery products

- Sauces, juices & jellies

- Meat & dairy products

- Wine

- Yogurt

- Chemical feed