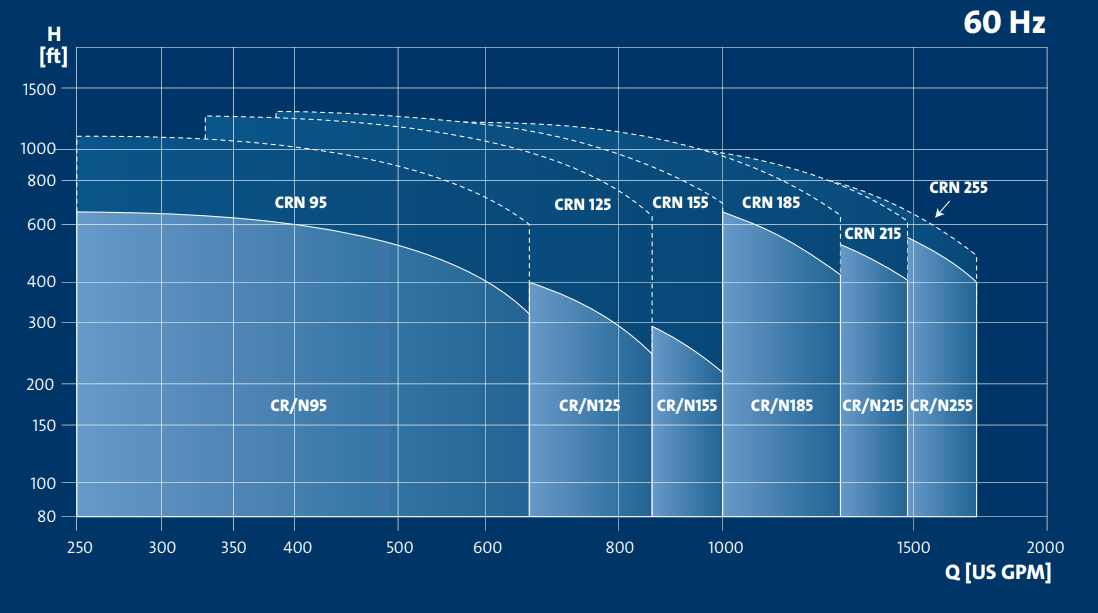

- First, here is the performance range of the old and new CR series.

- As you can see, the performance coverage of the new range is more than doubled compared to the old range.

- These performance improvements mean more possibilities for customers especially in the water utility market. For example, they can provide drinking water to more consumers (bigger plants), or they can provide water in bigger buildings or higher buildings than the past.

- In booster systems and other applications that use several CR units, customers can now reach their performance targets using fewer pumps – or more consumers than previously.

- Higher pressure of the new CR range is good news for customers with pressure demanding treatment applications.

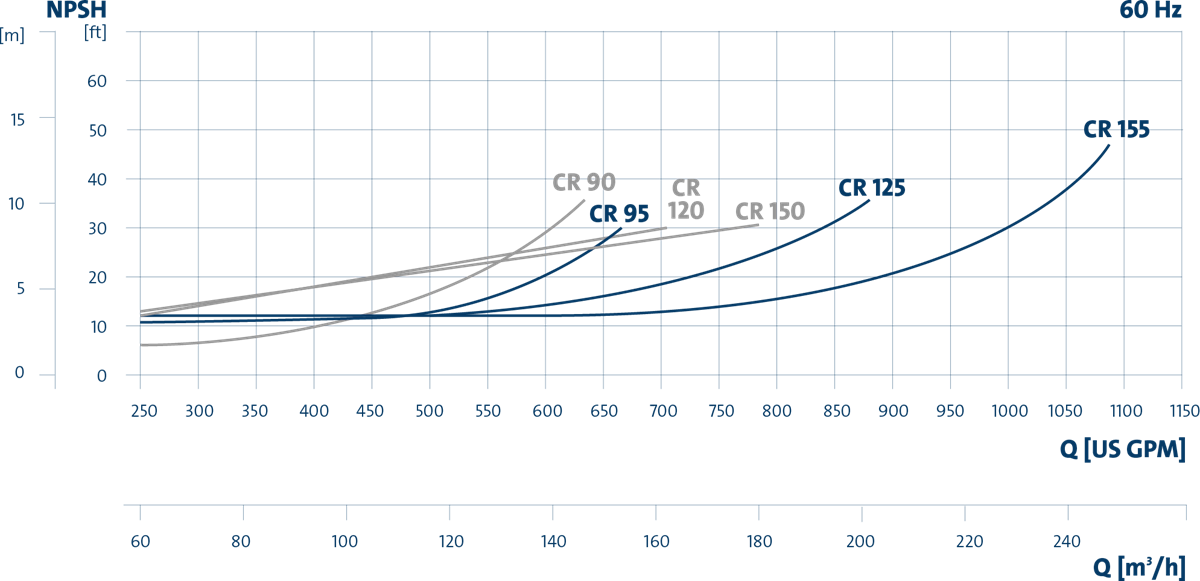

- And finally, we compare the old and new range in terms of NPSH (Net Positive Suction Head).

- The new range has significantly lower NPSH than the old one. This allows for more compact installation, for example in boiler feed applications, where now feeding tanks can be mounted at lower level or in negative suction-pressure installations (e.g. mounted on a tank) where we can perform with deeper suction depth.

- It also means that the new pumps are simply more robust, the risk of cavitation is lower in case the pump ”runs out the curve”. In other words, it’s also very much about reliability, which has always been one of the main advantages of the CR range.

- On larger pumps, the most frequently serviced components are the shaft seal and the motor bearings, and cavitation is a frequent cause of pump failure. With the new CR range, we are doing something about all of this:

- The shaft seal on the CR range is developed by Grundfos. The seal is available in many different material combinations to suit various liquid, pressure, and temperature requirements. Thanks to the balanced design, the seal is able to withstand a great amount of pressure. These two factors combine to give the shaft seal a long service life, and when it does need to be replaced, the cartridge design means that it can be replaced in minutes without using special tools.

- On the new CR range, a new thrust handling device, or THD. The THD cancels out axial thrust by using the pump discharge pressure. This prolongs the service life of the pump motor, and it allows us to use ordinary motor bearings in the pump, lowering spare part costs while extending the pump lifecycle. The THD is a standard feature on all models from 75 kW and up.

And finally, the new CR range to offer world-class NPSH. This, combined with the fully laser-welded impellers and chambers reduces the risk of cavitation and increases the robustness and life cycle of the pump