Brazed Plate Heat Exchanger

High performance: Brazepak copper brazed plate heat exchangers offer the highest level of thermal efficiency and durability in a compact, low cost unit. The engineered corrugated plate design provides very high heat transfer coefficients resulting in a smaller heat exchanger. Comparing the Brazepak to conventional shell and tube units:

- 1/6th the size

- 1/5th the weight

- Requires 1/8th the fluid charge

- 1/3rd to 1/5th the surface area

Solid self-contained unit: Thin corrugated stainless steel plates are vacuum brazed together to form a very durable, integral piece that can withstand both high pressure and temperature.

Numerous applications: Brazepak units are ideal for industrial, residential, commercial, and HVAC applications including but not limited to refrigerant evaporators and condensers, desuperheaters, subcoolers, economizers, heat recovery, oil coolers, and domestic water heaters and coolers.

Design features and options:

- 150 psig, 435 psig, and 650 psig standard options

- Custom designs up to 2000 psig

- 316L stainless steel plates with copper braze

- Single and double wall options

- Single and dual circuit options (e.g. refrigerant evaporators and condensers)

- Refrigerant distribution devices (i.e. refrigerant evaporator)

- Same day shipment available for standard stock units

- Standard and custom connection options

- Standard and custom mounting options

- ASME (U and N stamp available), UL, CRN, PED, ABS, KGS code options

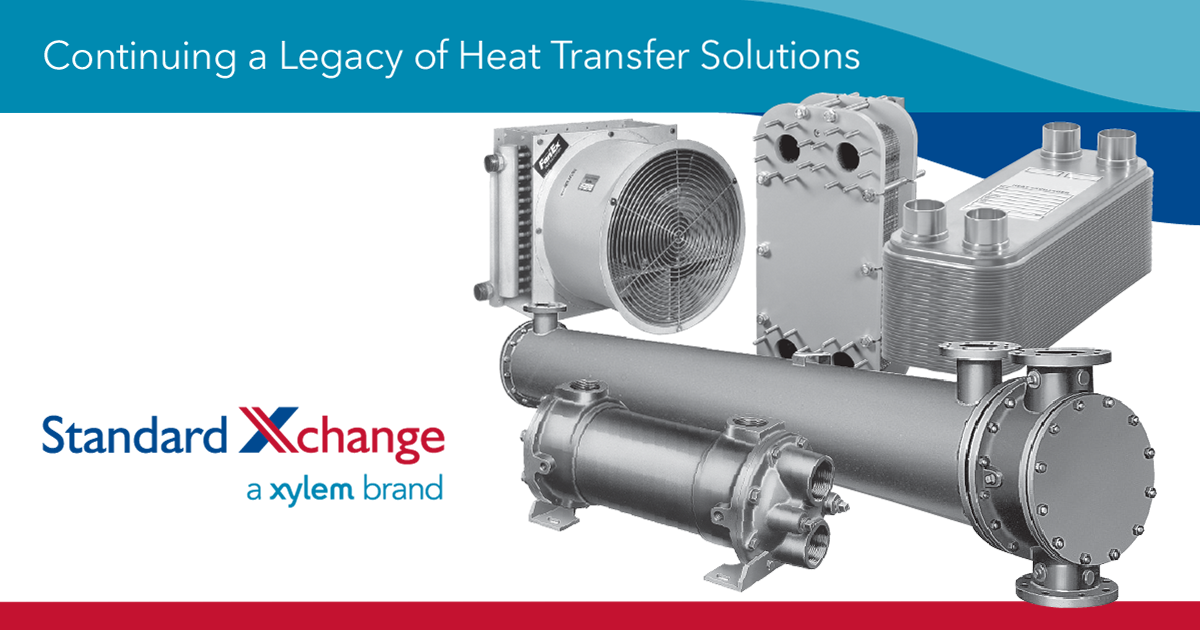

Plate & Frame Heat Exchangers

Plate and Frame heat exchangers use a combination of chevron-style heat transfer plates sequenced between a frame plate and pressure plate. The heat transfer plates have holes at the four corners forming a header that distribute the respective flows to the opposite sides of each plate when the plates align. The fluids are confined to the heat transfer surface of the plate or the port as appropriate with elastomer gaskets. Max Flow – up to 30,000 GPM with heat transfer areas up to 47,000 Sq. Ft. 1″ to 2.5″ NPT nozzle connections. 3″ to 24″ ANSI Studded connections.

Materials: 304 and 316 Stainless Steel, Titanium, SMO 254, Hastelloy, Incolloy, AL6XN Plates. Gaskets in Nitrile, EPDM, Viton, high temperature EPDM and high temperature Nitrile. Other materials available upon request.

Applications: Include but not limited to: heat recovery, equipment heating/cooling, make-up water preheating, chemical processes, central water, stator water, oil, auxiliary water, jacket water, drilling fluid. Double wall plates to reduce the possibility of fluids intermixing. Semi-welded for refrigeration or where reducing the fluid’s contact with elastomers is desired. Free Flow is ideal for pulp and paper or ethanol/biodiesel processes.

Features and Benefits:

- Higher surface area to volume ratios than conventional shell and tube heat exchangers

- Superior heat transfer coefficients compared to shell and tube heat exchangers

- Offers “true” countercurrent flow, which maximizes the mean temperature difference between fluids

Pre-Engineered Shell & Tube Heat Exchangers

Pre-engineered, fixed tubesheet models available for quick delivery. Brass, 316 S/S and Carbon Steel shell options. Copper, 90/10 CuNi and 316 S/S tube options. Select from 1, 2 or 4 passes, covering areas as large as 250 square feet. U-tube, removable bundle models also available in 2, 4, and 6 passes, covering areas as large as 1900 square feet.